October 16, 2020

Novel design and strategic use of materials in a pressure-sensitive adhesive strip

(LOS ANGELES) – In recent years, the use of wearable sensing devices has become a part of people’s everyday lives. Devices such as smart watches, for example, can be used to monitor physical fitness functions such as heart rate, sleep and exercise.

But advances in technology have opened many more possibilities for monitoring patient health. Sensors can now measure important health indicators such as metabolites, oxygen or therapeutic drug levels in the blood using wearable or hand-held devices. This allows patients an easy method of performing continuous, less invasive, real-time testing at home for diagnostic or treatment purposes. Having such a system profoundly impacts both patient and caregivers’ needs, decreasing the requirement for frequent hospital appointments and encouraging compliance with treatment.

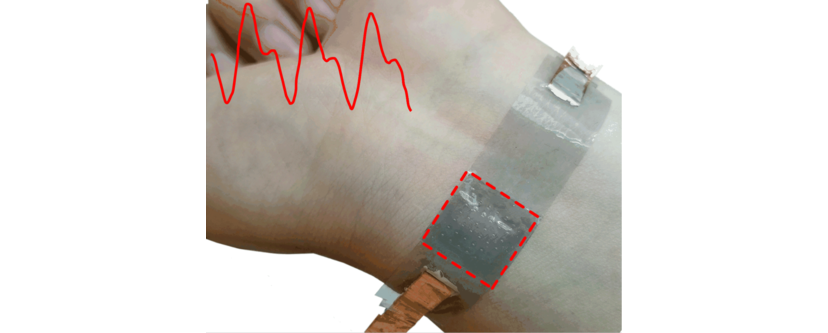

One type of these sensing devices is designed to respond to very small changes in bodily pressure, so that physical functions such as pulse rate, blood pressure, breathing rates and even subtle changes in vocal cord vibrations can be monitored continuously with a high degree of sensitivity. This pressure-sensitive device is fashioned into an adhesive strip, which is then applied to the skin at the wrist or neck pulse points. Measurement of these physical functions can be as simple as applying the sensor to the skin, then uploading the collected data for the physician to access remotely.

Pressure-sensitive devices should be made with materials which have good elastic and mechanical properties. The materials should also be compatible with and conform well to the surface of the skin. In the last decade, a variety of both natural and synthetic materials have been tested, but it was found that their physical characteristics were less than optimal.

Different types of a gel-like material called hydrogels provide superior physical qualities for pressure-sensitive devices, but pose their own set of problems: water evaporation, structural weaknesses and the lack of large-scale, cost-effective production methods.

A collaborative team, which includes a group from the Terasaki Institute for Biomedical Innovation, has devised solutions to the problems presented in constructing wearable pressure-sensitive sensors. The team chose a gelatin-based hydrogel due to its superior elastic properties, skin compatibility and low cost. It also offers ways to fine tune its elastic properties, structural characteristics, and pressure sensitivity by varying its preparation methods and the concentration of its components. This hydrogel has the added feature of transparency upon solidification, which makes it attractive for use as a wearable biosensor.

The team conducted extensive experiments to optimize the conditions needed to prepare the hydrogel with the desired characteristics. They then assembled it, along with transparent electrical components, into a fully-transparent strip that contained the hydrogel layer embedded into it.

“The advancements we have achieved with our hydrogel sensors have enabled us to successfully overcome the challenges from previous efforts,” said Shiming Zhang, Ph.D., part of the Terasaki Institute’s research team. “This will enhance the use of pressure-sensitive devices for many possible medical applications, which may include not only the continuous monitoring of blood pressure, pulse and breathing rates but also measuring vocal cord vibration for the early detection of voice and swallowing problems.”

To improve the overall durability of the finished product and guard against water evaporation from the hydrogel layer, the team added additional steps into the fabrication process: the assembly was treated with a chemical to provide added strength and the solidification of the hydrogel layer was strategically timed to produce optimum binding to the electrical components which surrounded it.

In another unique step in the fabrication process, one surface of the hydrogel layer was molded into a grid pattern consisting of pyramid-shaped projections that helped to increase the pressure sensitivity of the finished sensor. This capability is optimizable by experimentation with the size and spacing of these projections to get the best results.

Extensive testing of this sensor by the team showed that the fabrication process successfully addressed the problems of water evaporation and structural weakness in a robust fashion. Furthermore, the sensor was able to measure pressure changes with a higher degree of sensitivity and consistency and could be produced at greater cost-effectiveness and scalability than in previously observed sensors.

“Wearable sensors are convenient and accessible tools for monitoring patient health, and this work facilitates their production,” said Terasaki Institute Director and CEO Ali Khademhosseini, Ph.D. “It synergizes well with our Institute’s Personalized Devices platform, which aims to develop smart devices for continuous monitoring in real time.”

Additional authors are Zhikang Li, Yihang Chen, Haonan Ling, Libo Zhao, Guoxi Luo, Xiaochen Wang, Martin C. Hartel, Hao Liu, Yumeng Xue, Reihaneh Haghniaz, KangJu Lee, Wujin Sun, HanJun Kim, Junmin Lee, Yichao Zhao, Yepin Zhao, Sam Emaminejad, Samad Ahadian, Nureddin Ashammakhi, Mehmet R. Dokmeci, Zhuangde Jiang and Ali Khademhosseini.

Financial support came from the National Institutes of Health (1R01HL140951-01A1, 1R01GM126571-01, 1R01GM126831-01, 1R01EB023052-01A1, the National Science Foundation of China (51805423, 51875449, 91748207, 51421004) and the International Postdoctoral Exchange Fellowship Program (20180067).